The Heartbeat of Smoothness: Unveiling the Finishing Sander Stator

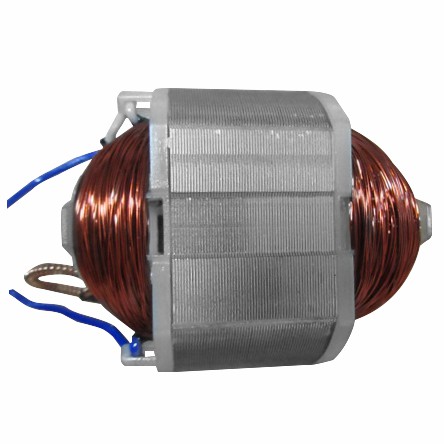

Within the unassuming housing of your finishing sander lies a crucial component: the stator. This electromagnetic powerhouse plays a vital role in driving the sanding action, transforming electrical energy into the force that powers the sanding pad. Here’s a breakdown of this essential part:

Function:

-

Power Converter: The stator receives electricity from the sander’s motor, typically through brushes or windings. This electricity creates a magnetic field within the stator’s core. This magnetic field interacts with magnets on the rotor (a rotating component) to generate torque, a twisting force. The torque causes the rotor to spin, ultimately driving the sanding pad.

-

Speed Demon (Indirectly): While the stator doesn’t directly control the sanding pad’s speed, it significantly influences it. The design and number of poles on the stator (electromagnetic protrusions) influence the interaction with the rotor and, consequently, the rotation speed.

Construction:

- Core: The stator’s core is typically made from laminated steel to minimize energy losses due to eddy currents. These laminations are thin sheets of steel electrically insulated from each other.

- Windings: Embedded within the core’s slots are insulated copper wires called windings. These windings create the magnetic field when electricity passes through them. The specific winding configuration can vary depending on the motor design (AC or DC motor).

- Frame: The stator is housed within a sturdy frame that protects the core, windings, and other internal components. This frame also provides a secure mounting point for the stator within the sander’s body.

Types of Finishing Sander Stators:

- Brushed Motors: Traditionally, brushed motors were commonly used in finishing sanders. These motors utilize brushes that make physical contact with the commutator (a part of the rotor) to transfer electricity. However, brushed motors can wear out over time and require brush replacements.

- Brushless Motors: Newer finishing sanders often incorporate brushless motors. These motors eliminate the need for brushes, resulting in a more compact design, reduced maintenance requirements, and potentially longer lifespan.

Maintenance Tips:

- While the stator is a robust component, it can benefit from preventive maintenance:

- Ventilation: Ensure proper ventilation for the sander to prevent overheating, which can damage the stator’s windings.

- Overload Prevention: Avoid overloading the sander by applying excessive pressure during sanding. This can strain the motor and potentially damage the stator.

- Cleaning: Regularly clean the sander’s dust collection system to prevent dust buildup, which can impede cooling and potentially affect the stator’s performance.

Replacement:

- Replacing a damaged stator can be a complex task, especially for non-professionals. Depending on the sander model and your expertise, consulting a qualified technician for stator replacement might be the best option. They can ensure the new stator is properly installed for optimal performance and safety.

In Conclusion:

The finishing sander stator, though hidden from view, plays a vital role in delivering the smooth sanding action you rely on. By understanding its function, construction, and maintenance needs, you can appreciate its importance and take steps to maintain your sander for optimal performance and longevity. Remember, when dealing with complex components like the stator, consulting a professional for repairs or replacements is often the safest and most reliable option.

Reviews

There are no reviews yet.