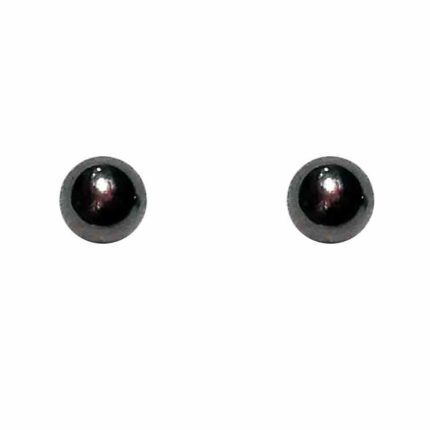

Impact Wrench Steel Ball: The Core of Power and Durability

The unassuming impact wrench steel ball plays a vital role in the immense power and durability of your impact wrench. This small, but critical, component lies at the heart of the impact mechanism, transferring the force from the motor to the socket with lightning-speed and impressive torque. Understanding the impact wrench steel ball and its function will ensure you select the right replacement and maximize the performance of your impact wrench.

What is an Impact Wrench Steel Ball?

The impact wrench steel ball is a hardened steel sphere located within the impact mechanism of your power tool. It sits between the hammer and the anvil within the housing. As the motor spins the rotor, the hammer receives rotational force. At a precise moment, the hammer disengages and slams into the anvil, driving the socket with a powerful blow. The impact wrench steel ball transmits this force efficiently, ensuring maximum torque is delivered to the fastener.

Qualities of a High-Quality Impact Wrench Steel Ball

- Material: Look for steel balls specifically designed for impact wrench applications. These balls are typically crafted from high-grade chrome molybdenum steel or similar high-strength alloys. This ensures they can withstand the incredible forces generated by the impact mechanism without deformation or shattering.

- Hardness: The impact wrench steel ball needs exceptional hardness to resist wear and tear. Look for balls with a Rockwell hardness rating above 60 HRC (Rockwell C Hardness).

- Precision: The size and weight of the impact wrench steel ball are crucial for optimal performance. A slight variation can affect the timing and efficiency of the impact mechanism. Ensure you purchase a replacement ball that matches the exact specifications of your impact wrench model.

Benefits of Using a High-Quality Impact Wrench Steel Ball

- Increased Power: A properly functioning steel ball ensures maximum force transfer from the motor to the socket, resulting in greater torque output for tackling tough jobs.

- Reduced Wear and Tear: High-quality materials and precise engineering minimize wear on the ball and other impact mechanism components, extending the lifespan of your impact wrench.

- Smoother Operation: A well-matched steel ball promotes smooth and efficient operation of the impact mechanism, reducing vibration and improving user comfort.

Replacing Your Impact Wrench Steel Ball

Over time, even high-quality steel balls can wear down or become damaged. Signs that your impact wrench steel ball may need replacing include reduced power output, increased vibration, or unusual noises during operation. If you suspect a faulty steel ball, consult your impact wrench manual for replacement instructions and ensure you purchase the correct size and type of ball for your specific model.

By understanding the impact wrench steel ball and its importance, you can ensure your impact wrench operates at peak performance for years to come. Invest in high-quality replacement parts to maintain the power and durability of your trusted impact wrench.

Reviews

There are no reviews yet.