The Powerhouse Within: Unveiling the Cut-Off Saw Rotor

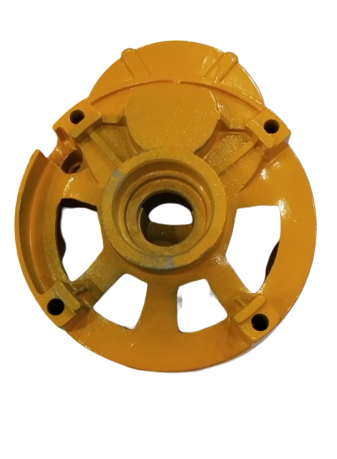

The unassuming cut-off saw rotor lies at the heart of this powerful tool, acting as the engine that drives the cutting wheel. Here’s a comprehensive breakdown of this essential component:

Function:

-

Power Converter: The cut-off saw rotor is responsible for converting electrical energy from the motor into mechanical energy. It accomplishes this through the interaction of electromagnetism. When electricity flows through the rotor’s windings, a magnetic field is generated. This magnetic field interacts with the stator’s stationary magnets, creating torque (twisting force). This torque causes the rotor to spin at high speed.

-

Speed Demon: The rotational speed of the rotor is crucial for the saw’s performance. The faster the rotor spins, the faster the cutting wheel rotates, allowing for efficient cutting of various materials like metal, concrete, or brick.

Construction:

- Core: The rotor’s core is typically made from laminated steel to minimize energy losses due to eddy currents. These laminations are thin sheets of steel electrically insulated from each other.

- Shaft: A central shaft made of high-strength steel runs through the core. This shaft connects the rotor to the gearbox and ultimately drives the cutting wheel.

- Windings: Embedded within the core’s slots are insulated copper wires called windings. These windings create the magnetic field when electricity passes through them. The specific winding configuration can vary depending on the motor design (AC or DC motor).

- Commutator (DC Motors Only): In DC motors, a commutator is a cylindrical component attached to the shaft. It consists of segmented copper bars and acts as a switch, reversing the current direction in the windings to maintain continuous rotation. AC motors don’t require a commutator.

Maintenance:

- The rotor is a robust component, but it can experience wear and tear over time due to regular use or excessive force. This can manifest as decreased performance, sparking, or even complete motor failure. Regular maintenance practices like avoiding overloading the saw and keeping the motor vents clean can help extend the rotor’s lifespan.

Replacement:

- Replacing a damaged rotor can be a complex task. Depending on the saw model and your expertise, it might be best to consult a qualified technician for rotor replacement. They can ensure the new rotor is properly installed and balanced for optimal performance and safety.

In Conclusion:

The cut-off saw rotor is the powerhouse behind the tool, transforming electrical energy into the rotational force that drives the cutting wheel. Understanding its function, construction, and maintenance needs allows you to appreciate its role and take steps to ensure your cut-off saw operates efficiently and safely for years to come. Remember, when dealing with complex components like the rotor, consulting a professional for repairs or replacements is often the safest and most reliable option

Reviews

There are no reviews yet.