Heat Gun Rivet: A Departure from the Traditional

The world of riveting has traditionally relied on dedicated rivet guns for creating permanent fastenings. However, the heat gun rivet offers a unique alternative, leveraging the power of heat for a different approach. Here’s a breakdown of this innovative solution:

Function:

- Heat-Activated Fastener: Unlike traditional rivets that require a mechanical squeezing action, heat gun rivets utilize heat activation. The rivet itself is a hollow shank with a small mandrel inside. When exposed to heat from a heat gun, the mandrel melts, causing the rivet shank to expand and fill the hole permanently.

Construction:

- Materials: Heat gun rivets are typically made from various materials depending on the application. Common materials include:

- Aluminum: Lightweight and good for general-purpose use.

- Steel: Stronger option for applications requiring higher load-bearing capacity.

- Stainless Steel: Offers corrosion resistance, ideal for outdoor or wet environments.

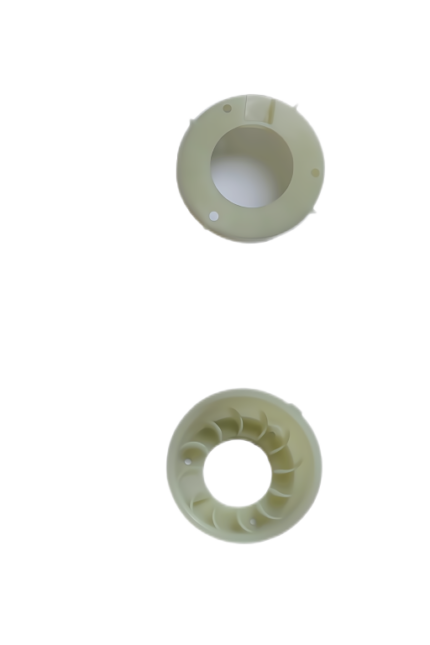

- Design: The design of a heat gun rivet is relatively simple. It consists of a hollow shank with a pre-inserted mandrel made of a lower melting point material compared to the shank.

Application Process:

- Preparation: Drill the appropriate size hole for the specific heat gun rivet you’re using. Ensure the surfaces to be joined are clean and free of debris.

- Heating the Rivet: Insert the heat gun rivet into the drilled hole. Using a heat gun on a suitable setting, direct the heat towards the mandrel end of the rivet.

- Expansion and Setting: As the mandrel melts from the heat, the rivet shank will begin to expand. Once the mandrel is fully melted and the rivet shank fills the hole, remove the heat source. The shank will cool and solidify, creating a permanent joint.

Benefits of Heat Gun Rivets:

- Versatility: Heat gun rivets can be used with various materials, including sheet metal, plastic, and some fabrics (depending on material compatibility).

- Accessibility: Since they don’t require a dedicated rivet gun, heat gun rivets can be used in tight spaces or areas where a traditional rivet gun might not fit.

- Clean and Quiet Operation: The heat activation process eliminates the noise and vibration associated with mechanical rivet guns.

Limitations of Heat Gun Rivets:

- Heat Source Dependence: You’ll need a readily available heat gun for using these rivets.

- Material Compatibility: Heat gun rivets might not be suitable for all materials, especially those susceptible to heat damage.

- Strength Considerations: While offering good holding power, heat gun rivets might not always match the strength achieved with traditional mechanical rivets, particularly for high-stress applications.

In Conclusion:

Heat gun rivets offer a unique and convenient approach to creating permanent fastenings. They are a versatile option for various materials and situations where accessibility or a quieter operation is desired. However, it’s crucial to consider the limitations, such as heat source dependence and potentially lower strength compared to mechanical rivets, when choosing the most suitable fastening method for your project.

Reviews

There are no reviews yet.