Impact Wrench Oil and Bearings: Understanding the Essentials

Impact wrenches are powerful tools that rely on a combination of compressed air, oil, and bearings to function effectively. Here’s a breakdown of their roles:

Impact Wrench Oil:

- Function: Impact wrench oil acts as a lubricant, reducing friction between moving parts within the mechanism. This minimizes wear and tear, prevents overheating, and ensures smooth operation.

- Type: There are two main types of oil used for impact wrenches:

- Air tool oil: This is a lightweight, non-detergent oil specifically formulated for pneumatic tools. It allows for quick movement of parts and helps prevent rust.

- Oil bath lubrication: In some impact wrenches, the entire front housing is submerged in a reservoir of oil. This method provides continuous lubrication but may not be suitable for all applications.

- Importance: Using the correct oil is crucial for maintaining your impact wrench. Improper lubrication can lead to:

- Increased friction and wear

- Seized or damaged parts

- Reduced performance and lifespan

Impact Wrench Bearings:

- Function: Bearings are precision components that allow for smooth, low-friction rotation between parts. In an impact wrench, bearings are typically located:

- Hammer mechanism: These bearings handle the high-impact forces generated by the hammering action.

- Drive shaft: The bearings support the rotation of the drive shaft, which transmits torque to the socket.

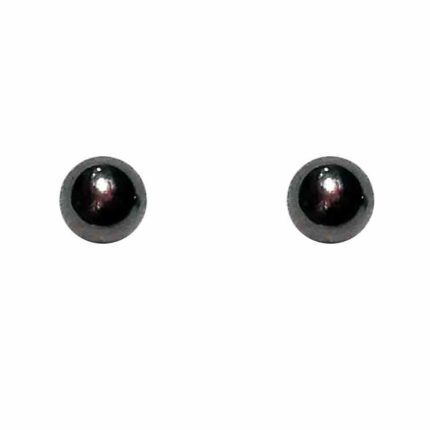

- Type: The specific type of bearing used will vary depending on the impact wrench design. However, they are often ball bearings or roller bearings made from high-strength steel to withstand the demanding environment.

- Importance: Properly functioning bearings are essential for efficient power transfer and smooth operation. Worn-out bearings can cause:

- Increased vibration

- Reduced power output

- Difficulty in maintaining consistent torque

Maintaining Your Impact Wrench:

- Consult the manual: Always refer to your impact wrench’s user manual for specific lubrication instructions and recommended oil types.

- Regular lubrication: Most impact wrenches require periodic oiling, typically after a certain number of uses or hours of operation.

- Oil changes: For oil bath systems, the oil may need to be changed periodically to remove contaminants.

- Bearing replacement: If your impact wrench experiences excessive vibration or power loss, worn bearings might be the culprit. Replacing them may be necessary, though this is often a job for a qualified repair professional.

By understanding the roles of oil and bearings in your impact wrench, you can ensure its smooth operation, extend its lifespan, and achieve optimal performance for your projects.

Reviews

There are no reviews yet.