The Engine of Hot Air: Unveiling the Heat Gun Motor

Within the unassuming shell of a heat gun lies a powerful force: the heat gun motor. This crucial component is responsible for converting electrical energy into the mechanical rotation that ultimately generates the intense heat flow characteristic of these versatile tools. Here’s a closer look at this essential part:

Function:

-

Power Converter: The heat gun motor receives electricity from the power cord. This electricity interacts with the motor’s internal components, typically windings and magnets, to create a rotating force. This rotational energy is then transferred to the fan, a vital component in the heat generation process.

-

Speed Demon (Not Always): While some heat gun motors achieve high speeds for optimal air circulation, others prioritize torque for generating concentrated heat at a slower air flow rate. The specific motor design and speed will depend on the heat gun’s intended use and overall functionality.

Construction:

- Types of Motors: Heat guns can utilize two main motor types:

- Universal Motors: These brushed motors are known for their simplicity, affordability, and ability to deliver high speeds, ideal for applications requiring high air flow for tasks like paint stripping or drying.

- AC Motors: These brushless motors offer advantages like increased efficiency, longer lifespan, and reduced noise compared to universal motors. They might be found in heat guns designed for generating concentrated heat for applications like heat shrinking or thawing pipes.

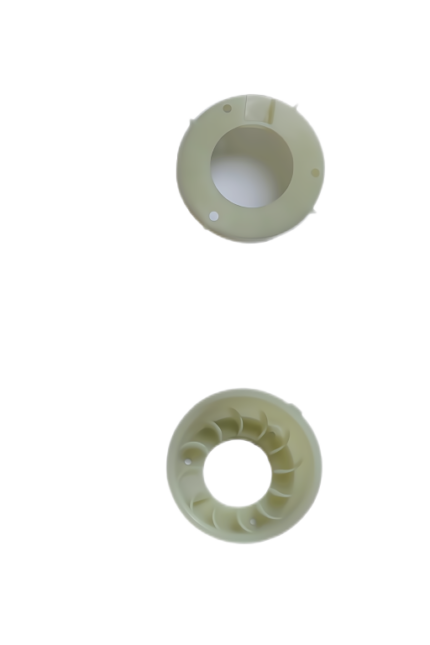

- Components: The core components of a heat gun motor typically include:

- Armature or Rotor: This rotating component interacts with the stator (stationary electromagnets) to generate torque. In universal motors, the armature has a commutator that reverses current flow to maintain rotation.

- Stator: This stationary component houses electromagnets that create a rotating magnetic field, which interacts with the armature to cause it to spin.

- Windings: Embedded within the armature or stator are insulated copper wires called windings. These windings create the magnetic field when electricity passes through them.

- Brushes (Universal Motors Only): These carbon brushes make contact with the commutator on the armature, transferring electricity to the windings.

Maintenance:

- Ventilation: The heat gun motor relies on proper ventilation to stay cool and prevent overheating. Regularly cleaning the air vents of your heat gun can help ensure optimal airflow and motor performance.

- Brushes (Universal Motors Only): Brushes in universal motors can wear down over time. Regularly checking and replacing worn brushes can help maintain motor performance and extend its lifespan. Brushless motors eliminate the need for brush maintenance.

Replacement:

- Replacing a heat gun motor can be a complex task. Depending on your expertise and the availability of replacement parts for your specific model, consulting a qualified technician for motor replacement might be the best option.

In Conclusion:

The heat gun motor is the driving force behind the intense heat generation capabilities of this versatile tool. Understanding its function, construction, and basic maintenance needs allows you to appreciate its role and take steps to ensure your heat gun performs efficiently and safely for extended use. Remember, when dealing with complex components like motors, consulting a professional for repairs or replacements is often the safest and most reliable course of action.

Reviews

There are no reviews yet.