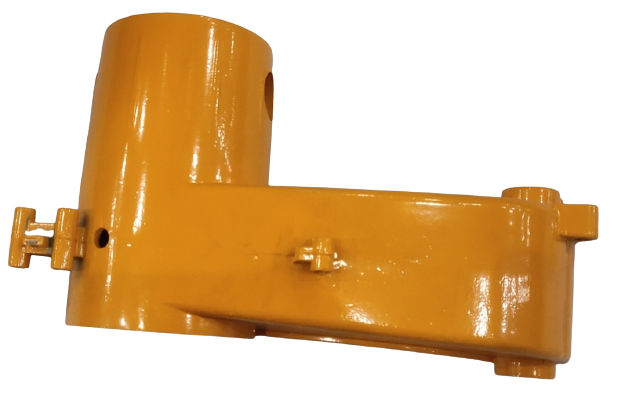

The Backbone of Power: Unveiling the Cut-Off Saw Motor Housing

Within the heart of your cut-off saw lies the motor housing, the essential component that safeguards the driving force behind every cut. Here’s a comprehensive look at this crucial element:

Function:

-

Protective Shell: The primary function of the motor housing is to act as a protective enclosure for the motor itself. It shields the motor’s internal components from dust, debris, and accidental impact during operation. This helps to maintain the motor’s functionality and extend its lifespan.

-

Heat Dissipation: The motor housing is often designed with vents or channels to facilitate proper heat dissipation. As the motor runs, it generates heat. The housing allows this heat to escape, preventing the motor from overheating and potentially malfunctioning.

-

Mounting Platform: The motor housing provides a sturdy platform for mounting the motor within the cut-off saw. This ensures the motor remains securely positioned and properly aligned with the saw’s drive components, such as the belt or gears, that transfer power to the abrasive cutting wheel.

Construction:

- Material: Motor housings are typically crafted from durable materials like aluminum or high-impact plastic. The choice of material impacts factors like weight, strength, and heat resistance.

- Design: The specific design of the motor housing can vary depending on the cut-off saw model. However, it generally features:

- Mounting Points: These are designated areas with screw holes or other mechanisms for securely attaching the motor housing to the saw’s frame.

- Vents/Channels: Openings within the housing allow for heat dissipation.

- Cable Access: An opening for the power cord to enter the housing and connect to the motor.

Maintenance:

- The motor housing itself generally requires minimal maintenance. However, maintaining proper airflow is crucial. Regularly cleaning the vents or channels with a compressed air can help prevent dust buildup and ensure optimal heat dissipation.

- Additionally, during cleaning, it’s advisable to inspect the housing for any cracks, warping, or loose mounting points. Damage to the housing can compromise motor protection and safety. If any such issues are identified, it’s best to consult a qualified technician for repair or replacement.

Replacement:

- Over time, the motor housing might experience wear or damage due to heavy use or accidental impact. In such situations, replacing the motor housing with a compatible model is necessary.

- When replacing the housing, ensure you choose one specifically designed for your cut-off saw model to ensure proper fit and functionality. It’s recommended to consult the saw’s manual or seek assistance from a qualified repair professional for guidance on selecting the right replacement housing.

In Conclusion:

The motor housing might seem like a simple component, but it plays a vital role in the safe and efficient operation of your cut-off saw. By understanding its function, construction, and maintenance needs, you can appreciate its importance and ensure your saw continues to deliver powerful performance for years to come. Remember, prioritize regular cleaning and inspect the housing for any damage. If replacement is necessary, choose a compatible model and consider seeking professional assistance for installation

Reviews

There are no reviews yet.