The Guardian of the Grind: Unveiling the Heat Gun Motor Housing

Within the heart of your heat gun lies the motor housing, acting as a protective shell for the vital components responsible for generating hot air. Here’s a breakdown of this essential element:

Function:

-

Protective Shelter: The primary function of the motor housing is to provide a secure and durable enclosure for the heat gun’s motor, brushes (if applicable), and other electrical components. This housing shields them from dust, debris, and potential damage during operation.

-

Heat Management: The motor housing is also designed to manage heat generated by the motor. It often features vents or openings that allow for air circulation, preventing excessive heat buildup within the housing. This helps to maintain optimal operating temperature for the motor and other components.

Construction:

-

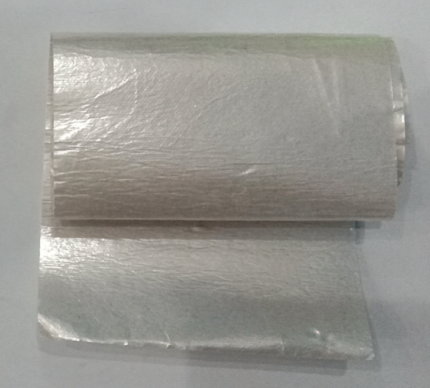

Material: Heat gun motor housings are typically crafted from high-temperature resistant materials like:

- Thermoplastics: These are lightweight and cost-effective options with good heat resistance.

- Nylon: Provides good strength, heat resistance, and insulation properties.

- Metal (Less Common): While less frequent, some high-performance heat guns might utilize metal housings for maximum durability and heat management.

-

Design: The specific design of the motor housing can vary depending on the heat gun model. It typically consists of two main parts:

- Base: The base provides a sturdy foundation for the motor and other components. It might also have mounting points for attaching the heat gun to a stand for hands-free operation.

- Upper Housing: This section covers the motor and other components. It often features openings for air intake and exhaust, as well as access points for brush replacement (if applicable).

Safety Considerations:

- Heat Dissipation: A properly functioning motor housing is crucial for heat gun safety. Ensuring the vents or openings are clear of debris allows for proper heat dissipation and prevents overheating.

- Electrical Safety: The housing should be free of cracks or damage that could expose electrical components, posing a potential shock hazard.

Maintenance Tips:

- Cleaning: Regularly wipe down the motor housing with a damp cloth to remove dust and debris accumulation. Ensure the vents or openings remain clear for proper air circulation.

- Visual Inspection: Periodically inspect the housing for any cracks, warping, or damage that could affect its protective capabilities or raise safety concerns.

Replacement:

- In cases of severe damage or melting due to overheating, replacing the motor housing might be necessary. Ensure you obtain a replacement housing specifically designed for your heat gun model for proper fit and functionality.

In Conclusion:

The heat gun motor housing, though seemingly simple, plays a vital role in the safe and efficient operation of your heat gun. By understanding its function, construction, and maintenance needs, you can ensure your heat gun performs optimally and remains a reliable tool for various tasks. Remember, prioritizing proper ventilation and inspecting for damage are key to maintaining a safe and functional heat gun.

Reviews

There are no reviews yet.