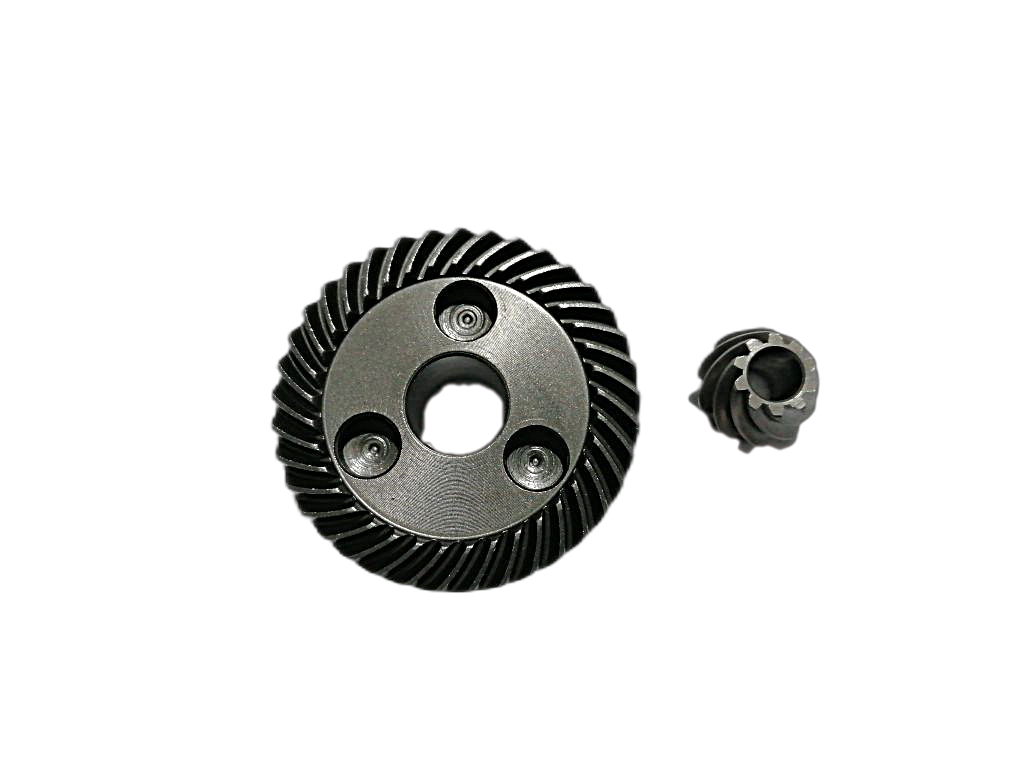

The Power Couple: Unveiling the Angle Grinder Gear and Pinion

Within the heart of your angle grinder lies a dynamic duo: the gear and pinion. These working partners are responsible for transferring the motor’s power to the grinding wheel, enabling you to tackle various cutting, grinding, and polishing tasks. Here’s a closer look at these essential components:

Function:

-

Power Transfer Team: The gear and pinion work together to efficiently transmit power from the motor to the grinding wheel. The motor spins a shaft connected to the gear. The pinion, a smaller gear meshed with the larger gear, then rotates at a higher speed due to its smaller size. This increased speed is then transferred to the grinding wheel mounted on the pinion shaft.

-

Gear Ratio Advantage: The difference in size between the gear and pinion creates a gear ratio. This ratio allows the grinder to achieve a higher rotational speed for the grinding wheel compared to the motor’s speed. This increased speed is essential for effective grinding and cutting operations.

Construction:

- Gear: The gear is typically a larger, toothed wheel made from high-strength steel. Its teeth mesh with the teeth of the pinion to create a positive, interlocking connection for power transfer.

- Pinion: The pinion is a smaller gear, also made from high-strength steel, that meshes with the gear. Due to its smaller size, it rotates faster than the gear, transmitting the increased speed to the grinding wheel.

Gear Types:

- Spiral Bevel Gears: These are commonly used gears in angle grinders. They have angled teeth that allow for smoother meshing and quieter operation compared to straight-cut gears.

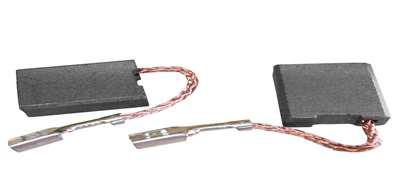

Maintenance:

- While the gear and pinion are generally durable components, they can wear down over time due to regular use or excessive force. This can manifest as noise, vibration, or reduced grinding performance. If you suspect wear or damage, it’s crucial to have a qualified technician inspect the gear and pinion and replace them if necessary.

Replacement:

- Replacing the gear and pinion is often a job for a professional technician. They have the expertise and tools to ensure proper alignment and meshing of the new gears for optimal performance and safety.

In Conclusion:

The gear and pinion are the unsung heroes of your angle grinder, working tirelessly behind the scenes to deliver power to the grinding wheel. Understanding their function, construction, and maintenance needs allows you to appreciate their importance and maintain your angle grinder for optimal performance and longevity. Remember, when it comes to gear and pinion replacement, consulting a qualified technician is the safest and most reliable option.

Reviews

There are no reviews yet.