The Powertrain Partner: Unveiling the Cut-Off Saw Gear

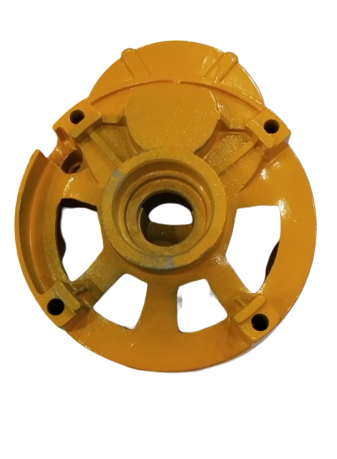

Within the heart of your cut-off saw lies a crucial duo: the motor and the gear. The gear acts as a vital partner in the powertrain, efficiently transferring the motor’s power to the abrasive cutting wheel, enabling you to tackle various cutting tasks in metal, concrete, or other materials. Here’s a detailed breakdown of this essential component:

Function:

- Power Transfer Champion: The cut-off saw gear works in conjunction with the motor to deliver power to the cutting wheel. The motor spins a shaft connected to the gear. The gear then meshes with another gear (often on the arbor) attached to the cutting wheel, increasing its rotational speed. This increased speed allows the cutting wheel to effectively cut through various materials.

- Gear Ratio Advantage: The design of the gears often incorporates a gear ratio. This ratio refers to the difference in size between the gear driven by the motor and the gear connected to the cutting wheel. A smaller gear on the motor shaft driving a larger gear on the arbor creates a higher speed for the cutting wheel, crucial for efficient cutting.

Construction:

- Material: Cut-off saw gears are typically crafted from high-strength steel. This ensures they can withstand the rigors of operation without bending, breaking, or wearing down prematurely.

- Gear Types:

- Spur Gears: These are commonly used gears with straight teeth that mesh directly with each other. They offer a simple and efficient design for power transmission.

- Helical Gears: Some cut-off saws might utilize helical gears with angled teeth. These gears offer smoother operation and reduced noise compared to spur gears.

Maintenance:

- While cut-off saw gears are generally durable components, they can experience wear and tear over time due to regular use or excessive force. This can manifest as noise, vibration, or reduced cutting performance. If you suspect gear problems, it’s crucial to consult a qualified technician for inspection and potential replacement.

Replacement:

- Replacing gears in a cut-off saw can be a complex task. Depending on the model and your expertise, it’s often recommended to seek professional help for gear replacement. A qualified technician can ensure the new gears are properly installed and mesh correctly for optimal performance and safety.

In Conclusion:

The cut-off saw gear, though a seemingly simple component, plays a vital role in the efficient operation of your saw. By understanding its function, construction, and maintenance needs, you can appreciate its importance and take steps to ensure your cut-off saw delivers clean and powerful cuts for years to come. Remember, for complex tasks like gear replacement, consulting a qualified technician is the safest and most reliable option.

Reviews

There are no reviews yet.