The Powerhouse Within: Unveiling the Cut Off Saw Gear Box

The unassuming gear box within your cut-off saw plays a critical role in transforming motor power into efficient cutting action. Here’s a breakdown of this essential component:

Function:

- Power Transfer Champion: The gear box acts as the heart of the power transmission system in your cut-off saw. It receives power from the motor and efficiently transfers it to the saw blade. This transfer involves two key functions:

- Speed Reduction: The motor typically spins at a very high speed. The gear box contains gears with different sizes. The larger gear connects to the motor, while the smaller gear connects to the saw blade shaft. This size difference creates a gear ratio, which reduces the motor’s rotational speed and increases its torque (twisting force). This increased torque is essential for the saw blade to cut through tough materials effectively.

- Directional Change: Depending on the gear box design, it might also change the direction of rotation from the motor to the saw blade. This ensures the blade spins in the correct direction for cutting.

Construction:

- Gears: The gear box typically houses multiple gears, each with a specific number of teeth. The specific configuration of gears determines the overall gear ratio and the final speed and torque delivered to the saw blade.

- Bearings: Bearings are placed strategically within the gear box to support the rotating shafts and gears. These bearings minimize friction and ensure smooth operation of the power transmission system.

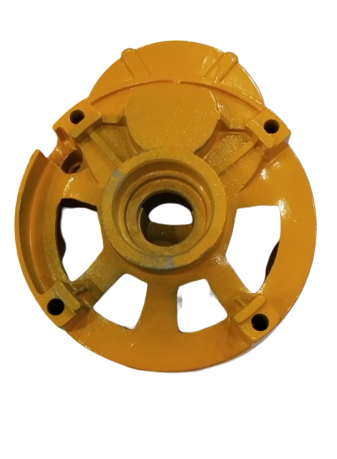

- Housing: The gear box is encased in a durable housing made of metal or a high-strength plastic material. This housing protects the gears and bearings from dust, debris, and potential damage.

Types of Gear Boxes:

- Worm Gear Drives: These gear boxes utilize a worm gear and a worm wheel. The worm gear has a screw-like thread that meshes with the teeth of the worm wheel. This type of gear box offers a very high gear reduction ratio, ideal for applications requiring significant torque at the saw blade.

- Spur Gear Drives: These gear boxes utilize sets of spur gears with interlocking teeth. Spur gear drives offer a simpler design and can provide a variety of gear ratios depending on the specific configuration.

Maintenance:

- The gear box is a relatively sealed unit and doesn’t require frequent maintenance. However, some gear boxes might have lubrication points that require occasional application of high-quality grease, specifically designed for power tools.

- Regularly cleaning the saw around the gear box area can help prevent dust and debris buildup that could potentially affect performance or longevity.

Replacement:

- If the gear box sustains damage or experiences excessive wear and tear, it might require replacement. Replacing a gear box can be a complex task, and depending on the saw model and your expertise, it might be best to consult a qualified technician for this job.

In Conclusion:

The gear box is the unsung hero within your cut-off saw, silently converting motor power into the necessary force for efficient cutting. Understanding its function, construction, and basic maintenance needs allows you to appreciate its role and take steps to ensure your saw operates smoothly and efficiently for years to come. Remember, when dealing with complex components like the gear box, consulting a professional for repairs or replacements can be the safest and most reliable option.

Reviews

There are no reviews yet.