The Powerhouse of Convenience: Unveiling the Cordless Impact Controller

The cordless impact controller has revolutionized the way we tackle fastening tasks. It combines the power of a traditional impact wrench with the freedom and maneuverability of a cordless design. Here’s a deeper look at this versatile power tool:

Function:

-

Fastening Force: The primary function of a cordless impact controller is to deliver high-torque rotational impacts to drive screws, nuts, and bolts. This makes it ideal for applications requiring high fastening power, such as:

- Driving large lag screws into decks or beams.

- Loosening stubborn rusted bolts on automotive projects.

- Quickly assembling furniture with numerous bolts.

-

Cordless Convenience: Unlike its corded counterparts, the cordless impact controller eliminates the need for a power outlet. This provides unmatched freedom of movement and eliminates the hassle of managing cords around your work area.

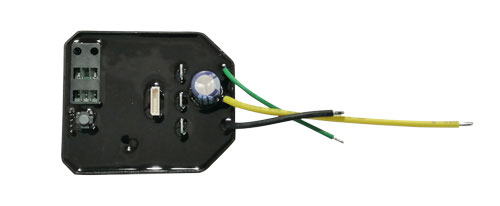

Construction:

- Motor: The heart of the controller is a powerful electric motor that generates the torque for driving fasteners. Brushless motors are often preferred for their efficiency and longer lifespan.

- Battery: The controller is powered by a rechargeable lithium-ion battery. Battery voltage (e.g., 18V, 20V) typically dictates the overall power of the controller. Higher voltage batteries generally deliver more torque.

- Chuck: The chuck is the mechanism that securely holds the drill bit or socket used for driving fasteners. Common chuck types include keyless chucks for easy bit changes and standard key chucks for a tighter hold on specific bits.

- Impact Mechanism: This internal mechanism translates the motor’s rotational force into a series of rapid, high-torque impacts. These impacts deliver the necessary force to drive fasteners into tough materials or loosen stubborn bolts.

- Variable Speed Trigger: The trigger allows for variable speed control, enabling you to adjust the rotation speed and impact rate for different tasks. This allows for precise control when driving delicate screws or using large fasteners.

- Ergonomic Design: Cordless impact controllers are designed with comfort and control in mind. They often feature soft-grip handles and lightweight construction to minimize user fatigue during extended use.

Benefits of Using a Cordless Impact Controller:

- Power and Portability: This tool combines the power of an impact wrench with the convenience of a cordless design, offering unmatched versatility for various fastening tasks.

- Increased Efficiency: The cordless design allows for faster setup and movement between work areas, boosting overall project efficiency.

- Reduced User Fatigue: Ergonomic design features and lighter weight contribute to a more comfortable working experience.

Important Considerations:

- Torque Output: The controller’s torque output is a crucial factor to consider. Higher torque is better for driving larger fasteners or working with tougher materials.

- Battery Life: Battery capacity (measured in amp hours, Ah) impacts how long the controller can operate on a single charge. Consider the types of jobs you’ll be tackling and choose a battery with sufficient capacity.

- Compatibility: Ensure the controller uses batteries compatible with other cordless tools you might own for a more unified and cost-effective power tool system.

In Conclusion:

The cordless impact controller is a valuable addition to any toolbox. Its potent combination of power, portability, and user-friendliness makes it ideal for tackling a wide range of fastening tasks. By understanding its functions, construction, and benefits, you can make an informed decision when choosing the right cordless impact controller for your needs. Remember to prioritize safety by always wearing proper eye protection and following the manufacturer’s instructions for safe operation.

Reviews

There are no reviews yet.