The Conduit of Power: Unveiling the Angle Grinder Carbon Brush

Within the heart of your angle grinder lies a seemingly simple yet crucial component: the carbon brush. These unassuming brushes act as the bridge between the stationary electrical supply and the rotating motor within the grinder, ensuring a smooth flow of electricity to power grinding operations. Here’s a deeper look at these essential elements:

Function:

-

Electrical Connection Champions: Carbon brushes make physical contact with the commutator (in DC motors) or slip rings (in AC motors) of the motor. These commutator/slip ring components rotate with the motor shaft. The brushes themselves remain stationary within a brush holder. As the motor shaft spins, the brushes transfer electrical current from the motor’s windings to the commutator/slip rings, creating the electromagnetism that drives the motor’s rotation.

-

Maintaining Contact: The brushes are designed to maintain constant yet gentle pressure against the commutator/slip rings. This ensures a good electrical connection and allows for current flow.

Construction:

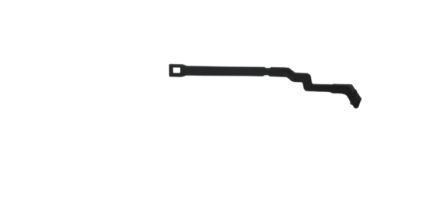

- Material: Carbon brushes are typically made from a combination of graphite and other conductive materials. This blend offers a balance of conductivity for efficient current transfer and hardness to withstand wear during operation.

- Spring Mechanism: The brushes are held in place by a spring mechanism within the brush holder. This spring applies the necessary pressure against the commutator/slip rings while allowing for slight movement to accommodate for wear.

- Brush Leads: Each carbon brush has a wire lead attached to its end. This lead connects the brush to the motor’s electrical supply.

Maintenance:

- Wear and Tear: Over time, carbon brushes wear down due to friction with the commutator/slip rings. This wear reduces their effectiveness in transferring current.

- Inspection and Replacement: Regularly inspect your angle grinder’s carbon brushes for signs of wear. Most manufacturers recommend replacing them when they reach a specific length (usually indicated by a wear mark on the brush). Worn brushes can lead to decreased motor performance, sparking, or even complete motor failure.

- Replacement Tips: When replacing carbon brushes, ensure you use brushes specifically designed for your angle grinder model. These brushes will have the correct dimensions and material composition for optimal performance and compatibility.

Safety Considerations:

- Power Disconnect: Always disconnect the angle grinder from the power source before inspecting or replacing carbon brushes.

In Conclusion:

Carbon brushes, though small, play a critical role in the smooth operation of your angle grinder. By understanding their function, construction, and maintenance needs, you can ensure your grinder receives the power it needs to perform effectively and safely. Remember, regular inspection and replacement of worn carbon brushes are key to maintaining optimal performance and preventing potential damage to your angle grinder’s motor.

Reviews

There are no reviews yet.