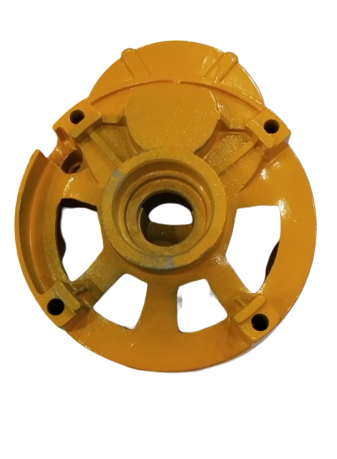

The Silent Guardian: Unveiling the Cut Off Saw Brush Holder

Within the heart of your cut off saw lies an unsung hero: the brush holder. Although seemingly simple, this component plays a vital role in the saw’s operation and performance. Here’s a breakdown of this essential part:

Function:

-

Electrical Connection Champion: The primary function of the brush holder is to securely hold the motor’s carbon brushes and maintain proper contact with the commutator (in a DC motor) or slip rings (in an AC motor). These brushes act as conductors, transferring electrical current from the motor’s stationary windings to the rotating commutator or slip rings, ultimately powering the saw’s motor.

-

Friction Fighter: The brush holder also applies a slight pressure on the brushes to ensure consistent and optimal contact with the commutator or slip rings. This minimizes friction and sparking while maximizing current transfer for smooth motor operation.

Construction:

- Material: Brush holders are typically crafted from a durable and heat-resistant material like insulated plastic or high-temperature nylon. This ensures they can withstand the heat generated during motor operation.

- Design: The design of the brush holder can vary depending on the motor type and saw model. However, they generally consist of a housing that holds the brushes and a spring mechanism that applies the necessary pressure. Some brush holders might incorporate features like wear indicators that alert you when the brushes need replacement.

Maintenance:

- Brush Wear and Tear: Carbon brushes are considered wear-and-tear items. Over time, they wear down due to friction with the commutator/slip rings. This can lead to reduced motor performance, sparking, or even complete motor failure.

- Regular Inspection: Regularly inspecting the carbon brushes for signs of wear (shortened length) is crucial.

- Replacement: When the brushes reach their wear limit, it’s essential to replace them with brushes specifically designed for your cut off saw model.

Safety Considerations:

- Using the Correct Brushes: Using brushes with the incorrect dimensions or material composition can damage the commutator/slip rings and compromise motor performance. Always consult your saw’s manual for the recommended brush specifications.

- Replacing Brush Holders: In some cases, the brush holder itself might become damaged or worn out. If you suspect a faulty brush holder, it’s advisable to consult a qualified technician for replacement.

In Conclusion:

The cut off saw brush holder, though a simple component, plays a critical role in the smooth operation and longevity of your saw’s motor. By understanding its function, construction, and maintenance needs, you can ensure your saw continues to deliver powerful and reliable performance. Remember to prioritize safety by using the correct brushes and consult a professional if you suspect a faulty brush holder.

Reviews

There are no reviews yet.